DXF Applications

Watercraft

Aerospace

Energy

Dosimetry

DXF offers an exciting opportunity to make a soft flexible skull cap that can be worn by patients during radiotherapy treatment to monitor and adjust the treatment plan during treatment. In addition, DXF can be used for beam and treatment plan calibration before treatment commences.

About Silveray

Our vision is to develop affordable large-area direct conversion detectors for the X-ray imaging market.

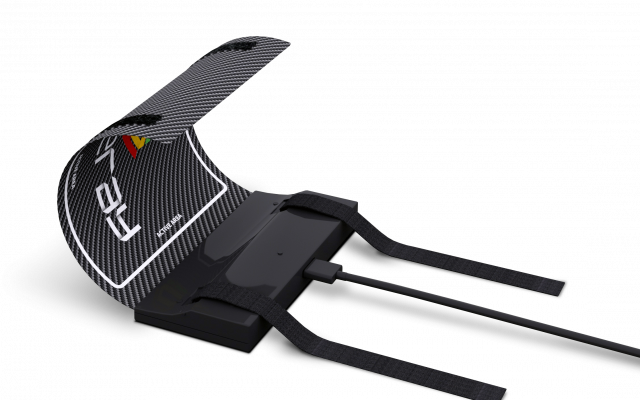

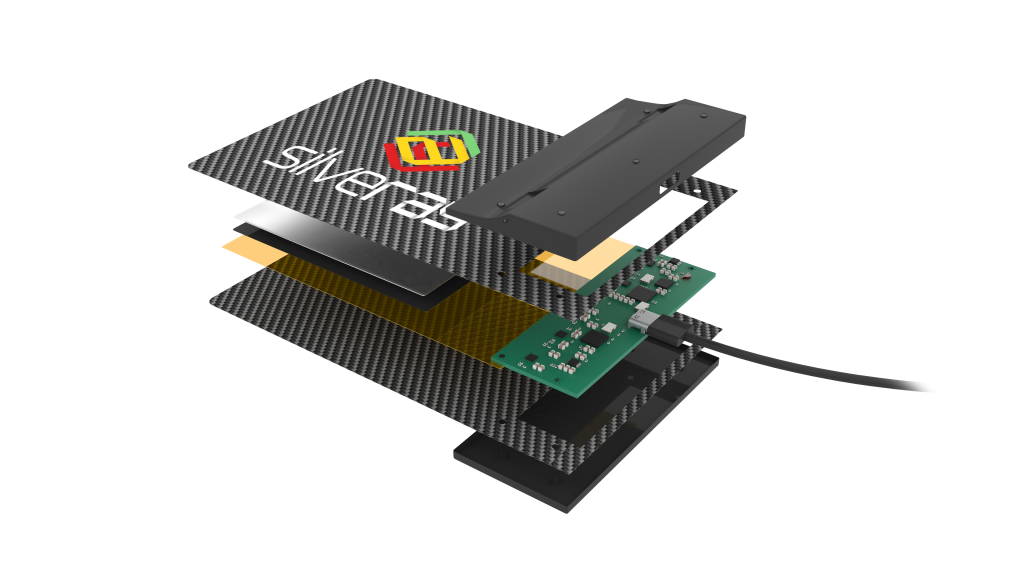

Our core technology is an X-ray sensitive semi-conductor ink called NPX®, which allows us to create large-area direct conversion X-ray and gamma ray detectors. These detectors can be made very thin and flexible to work over a large range of X-ray and gamma ray energies.

Technology

High performance

The high X-ray imaging performance comes from the direct conversion capability of the material. Most traditional X-ray detectors use indirect conversion, which trades off resolution (how much detail you can see in an image) against dose efficiency (how many X-rays are needed to create a useable image). Direct conversion detectors are now accepted in the market for delivering best-in-class X-ray image sharpness, higher throughput for in-line inspection, and low dose performance for medical. However, these direct conversion detectors come at a significant cost premium due to their high material & processing costs.

Excellent from low to high X-ray energies

As the nanoparticles that are used to block the incoming X-ray photons are selected to have a high X-ray attenuation (with a high atomic number ‘Z’ in the periodic table of elements), our material is particularly well suited to the inspection of challenging industrial products. Where thick objects (such as steel) need to be inspected at higher X-ray energies to ensure that the X-rays can penetrate the object under test, our material offers a new alternative for non-destructive testing (NDT).

Lower cost

Our X-ray conversion material is based on a semiconductor ink and is therefore printable using common coating techniques. This enables significantly lower production costs compared to other conversion materials (for example CdTe, CZT, and even structured CsI). Our technology enables us to offer a price-competitive alternative for large-area direct conversion detectors.

Relevant publications

NEWS

Contact Us

Silveray’s operations are based at Pear Mill in Stockport (Greater Manchester, UK) with in-house optoelectronic device fabrication amenities, cleanroom facilities, and electronics lab space, as well as offices and meeting areas.

The company also has a presence at STFC’s facilities in Daresbury Lab, where it maintains close links to the local research community in the North West region of the UK.

Silveray

Pear Mill Industrial Estate

Stockport Road West

Stockport, SK6 2BP

United Kingdom